Getting the Point

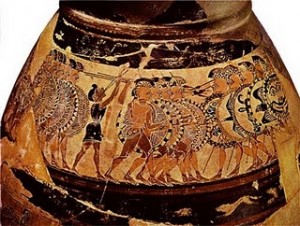

The Macedonian Phalanx was a battlefield formation developed by King Philip, father of Alexander the Great. It was the most effective military ground weapon to meet enemy forces head on, enabling attack by cavalry and other forces along the flanks. It utilized collapsible long spears and was virtually undefeatable for over 300 years. It combined the interlocking and cohesion of shields and the long reach of the spear. The units were well trained. It was a marvelous combination of strategy, technology, resources, process and, execution. Sounds like a phrase of a business book. The phalanx had worked so well, that it changed very little strategically until the Battle of Pydna in 186 BC when Roman Legions massacred the Macedonians. The Romans also combined strategy, technology, resources, process, and execution. There is one contrasting difference, the phalanx was a weapon built on rigidity, and these Roman legions applied agility against their enemy. The phalanx was vulnerable on uneven ground, the flanks and rear and was next to useless close up. The Roman gladius was the epitome of a close battle weapon, a breakthrough technology, one that moved from bronze and iron to forged steel.

The Macedonian Phalanx was a battlefield formation developed by King Philip, father of Alexander the Great. It was the most effective military ground weapon to meet enemy forces head on, enabling attack by cavalry and other forces along the flanks. It utilized collapsible long spears and was virtually undefeatable for over 300 years. It combined the interlocking and cohesion of shields and the long reach of the spear. The units were well trained. It was a marvelous combination of strategy, technology, resources, process and, execution. Sounds like a phrase of a business book. The phalanx had worked so well, that it changed very little strategically until the Battle of Pydna in 186 BC when Roman Legions massacred the Macedonians. The Romans also combined strategy, technology, resources, process, and execution. There is one contrasting difference, the phalanx was a weapon built on rigidity, and these Roman legions applied agility against their enemy. The phalanx was vulnerable on uneven ground, the flanks and rear and was next to useless close up. The Roman gladius was the epitome of a close battle weapon, a breakthrough technology, one that moved from bronze and iron to forged steel.

The Macedonians experienced a disruption in their capability; they did not decay battle by battle. Content with the phalanx, they continued to make it better, each day, and becoming less likely to win against the Romans. They suddenly discovered and dearly paid the Cost of Unreadiness. Over the last few years evidence of the Cost of Unreadiness has been unavoidable. We saw it in the recession triggered by the meltdown, to the ravages of earthquakes and tsunamis, lagging or no capability in response to Katrina, incompetence with the oil spill; there are plenty to consider.

So, there is such a category of cost and it can be so high that it can be terminal, life ending, for humans or businesses. This cost is part of a family of costs we don’t measure, but we experience. We budget for them, but not explicitly, rather they are buried in our standards and estimates, processes, and plans. Traditionally, Lean has sought to reduce the costs of imbedded waste, Six Sigma attacking the costs from unwanted variation. In our current environment, full of complex systems, interdependencies, changing requirements, these other costs are likely to grow, perhaps with emphasis on the costs of unreadiness and rigidity.

Looking back at the last few years, how did your enterprise fare with:

• Disruptions?

• Reduced capability?

• Consequences from unplanned events?

• Costs from rigidity?

• Costs from unreadiness?

• Lessons learned?

• Changes in strategy, technology, resources, process and, execution?

Are we ready for the next surprise? Any thoughts?